Written by Victorian Solan, Consultant Historian for GLOW

Neon signs were once so ubiquitous that it is easy to overlook the fascinating mix of craftsmanship, art, and chemistry which each sign-maker had to master in order to bring blinking bicycle wheels and flashing rockets to Massachusetts roadsides.

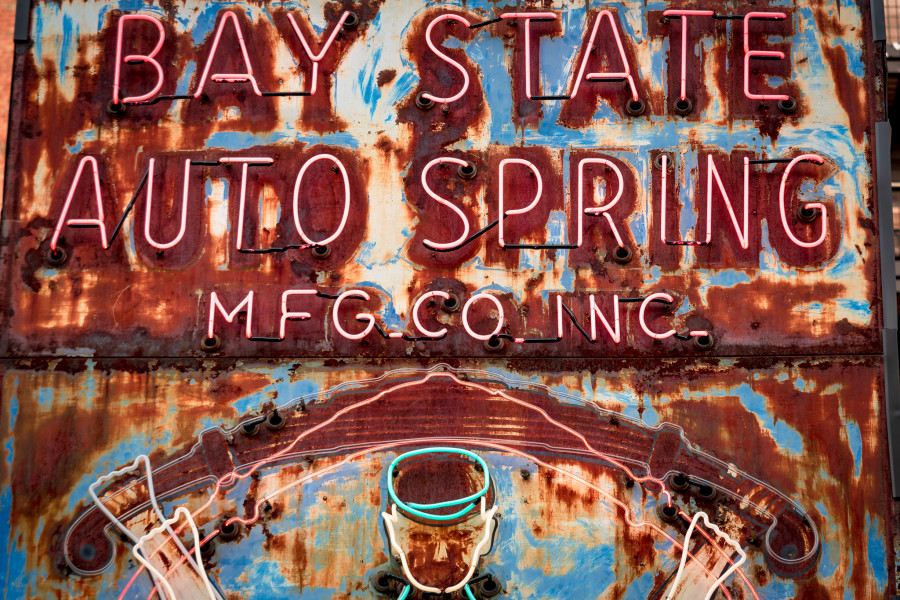

Although the shapes and colors vary, all neon signs operate on the same simple scientific principle: an electrical current passes through a sealed glass tube filled with a stable, inert gas, usually neon or argon. The gas in the tube glows when it is charged, emitting a steady stream of light. The illusion of movement on a particular sign, such as the flexing of the Bay State leaf spring, is created by lighting different sections of sealed tubing on simple timers. In darkness, the unlit tubes disappear into the background, while the charged tubes glow with their distinctive glare.

Neon gas was first identified by the Scottish chemist William Ramsay in the late 19th century, who won the Nobel Prize for chemistry in 1904. French inventor Georges Claude displayed the world’s first neon lights at the Paris Exposition in 1910. Claude, who was a savvy entrepreneur, as well as a talented chemist, patented his method for capturing and electrifying the several gases used in neon lights. Most of the early neon signs made in France and the United States were made by Claude’s employees and license-holders. Claude, who moved into the field of chemical weapons, allowed his patent to expire in the 1930s. After that, hundreds of sign-makers moved into the business, filling the roadside with colorful, creative illuminated signs.

Today, neon signs are still made by hand, using a blend of ancient glass-blowing technique, 20th-century chemistry, and contemporary design. First, the sign-maker traces an outline of the desired shape or lettering onto paper. The letter forms must be continuous for the gas to flow evenly from one end of the sign to the other. After selecting the desired length of industrially-produced glass tubing, the sign-maker heats the glass over a small flame, bending it to conform precisely to the pre-selected shape. At the same time, he or she must maintain airflow through the tube, usually by blowing through a simple piece of rubber tubing attached to one end of the glass tube. Although the process of bending the glass tubes is relatively simple, it takes years of practice to attain the precision required for the elaborate shapes in many of the sign on display in GLOW.

Once the glass is formed into the desired sequence of curves and straight lines, the sign-maker must shift from artisanal work to the practice of chemistry and physics. First, he or she fuses electrodes to each end of the shaped tube. Then, the tube must be cleansed of all impurities during a heated process called bombardment. Heat is also used to create a vacuum inside the tube; neon or argon gas can then be added to a desired pressure point calculated from the diameter of the glass tube. If the sign-maker executes this process properly, the tube can last for decades.

The glowing line of light on a neon sign is always the result of charged gas particles trapped in a sterile, transparent environment. Carrying the electrical charge from the electrodes at each end of the finished tube, each atom of neon sheds photons which our eyes read as colored light. True neon gas glows reddish-orange, while argon emits a bluish light. Other colors can be made by varying the color of the tubing which houses the gas. Sections of the illuminated tube are painted black or another opaque color to create the illusion of space between connected letters or forms. Finished tubing is then mounted on a sign board, electrical wiring is concealed in discreet metal housing, and the illuminated sign is ready for use. The entire process is illustrated in a wonderful short video by Stereokroma TV, showing master sign-maker Gerald Collard making a neon sign in his Montreal studio.

Photos courtesy of Rich Colicchio Photography